316 Stainless Steel Plate

AISI316 / SUS316 (1.4401)

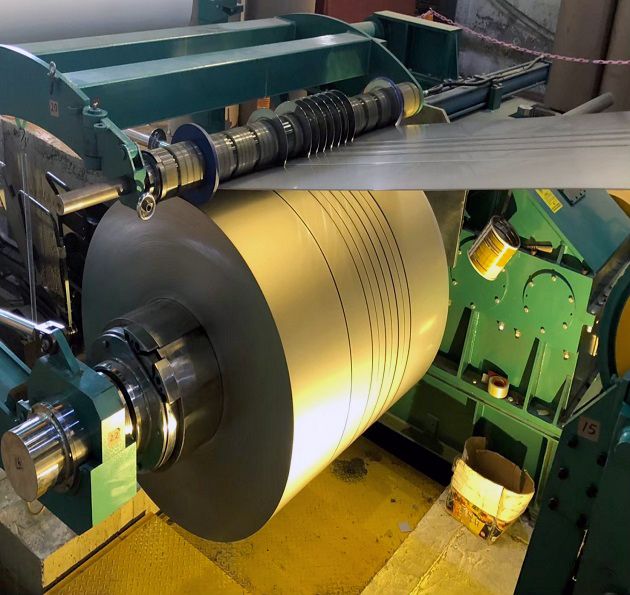

316 stainless steel plates include grade: AISI / SUS 316 (1.4301), thickness: 6.0mm ~ 16.0mm, surface finishes: BA, NO1, NO4, HL, NO8, width: 1219mm, 1250mm, 1500mm, 1524mm. Length range: 200mm ~ 6100mm. Our stainless steel plate production line implements comprehensive management, from strict selection of raw materials to quality inspections prior to shipment. We have established stringent standard procedures to ensure product quality. All raw materials are sourced from internationally renowned manufacturers to ensure compliance with international standards. We place great emphasis on product quality, implementing end-to-end management throughout our production line.

The following are the common stock sizes of 316 stainless steel plates:

4 feet x 8 feet (1219mm x 2438mm)

4 feet x 10 feet (1219mm x 3048mm)

5 feet x 8 feet (1524mm x 2438mm)

5 feet x 10 feet (1524mm x 3048mm)

HE-TIEN provides detailed services for 316 stainless steel plates, including customization of length according to customer requirements and edge trimming services. Our HL (hairline) and NO.4 surfaces are achieved through flat dry sanding. Additionally, we offer double-sided sanding services for HL and NO.4 finishes. For applications requiring high reflectivity and smoothness, we also provide Bright Annealed (BA) and Mirror (NO.8) finishes with double-sided polishing.

We offer various protective film options such as PE blue film, PVC black/white film, CO2 laser film, and fiber laser film to safeguard the plates during processing and handling. Furthermore, our material inkjet printing services allow for professional and personalized labeling directly on the 316 stainless steel plates, perfect for branding and ensuring product traceability.

HE-TIEN collaborates with numerous technology industries, providing them with high-quality stainless steel plate products. Our stainless steel plates are widely used in sectors such as semiconductors, electronics, medical devices, clean energy, and environmental engineering. Our products not only offer excellent corrosion resistance and durability but also maintain high levels of consistency and precision in the manufacturing process, ensuring that each plate meets the strictest quality standards.

Our advanced processing equipment and professional team ensure the accuracy and quality of our products. The double-sided sanding and protective film application services effectively protect the stainless steel plates during processing and handling. Additionally, our material inkjet printing services allow for professional and personalized labeling directly on the stainless steel plates, perfect for branding and ensuring product traceability.

We are dedicated to meeting the diverse needs of our customers, providing exceptional service from initial consultation to final delivery. Our long-term collaborations with many technology industries demonstrate our outstanding capability in delivering high-quality stainless steel products and services. By choosing HE-TIEN as your 316 stainless steel plate supplier, you will receive unparalleled product quality and customer support. We look forward to working with you and helping your business thrive with our superior products and services.

Product Specification

- ASTM A240/A240M/A480/A480M

- JIS G4305/G4304

- EN 10028-1/10088-2

Stainless Steel 316 Features and Applications

316 stainless steel plate is a highly corrosion-resistant steel grade that possesses the following characteristics:

High Corrosion Resistance: It exhibits good resistance to corrosion in various corrosive media such as seawater, acids, and alkalis.

High Oxidation Resistance: It effectively resists oxidation and corrosion in high-temperature and oxidizing environments, including hot water, steam, and chemicals.

High Strength: It maintains high strength and ductility even at high temperatures and under high-pressure conditions.

Good Processability: It is easy to cut, weld, and shape during processing.

The key difference between 316 stainless steel and other stainless steel grades lies in its higher content of molybdenum, which enhances its corrosion resistance and oxidation resistance. As a result, it is more suitable for applications requiring excellent corrosion resistance and resistance to high temperatures and pressures compared to stainless steel 304.

316 stainless steel plate is widely used in industries such as chemical processing, pulp and paper, marine engineering, food processing, medical devices, and architectural decoration. For example, it is employed in the manufacturing of medical instruments and surgical tools, fabrication of kitchen and bathroom equipment and appliances, and production of high-quality chemical equipment and pipelines. Additionally, 316 stainless steel finds applications in the marine and petroleum industries for the construction of offshore platforms, saltwater pipelines, and chemical reactors, among other equipment.

Stainless Steel 200 / 300 / 400 Series Characteristics

Stainless steel plate is typically composed of iron, carbon, chromium, nickel, cobalt, and other alloying elements. Stainless steel can be divided into three series: 200 series, 300 series, and 400 series, which differ in the type and proportion of alloying elements.

200 Series: Primarily containing nickel and manganese but no chromium, they have poorer corrosion resistance but good ductility and formability, making them easy to process and shape. Products made from 200 series stainless steel include kitchen utensils, furniture, pipes, and building structures.

300 Series: Primarily containing chromium and nickel but no molybdenum, they have excellent corrosion resistance and high-temperature performance, making them particularly suitable for use in industries such as chemical, petroleum, and food processing. The most common of these is 304 stainless steel, which has a wide range of applications including kitchen utensils, food processing equipment, medical devices, building exterior decoration, and more.

400 Series: Primarily containing chromium and molybdenum but no nickel, they have poorer corrosion resistance but good heat and wear resistance, making them particularly suitable for use in industries such as mechanical and automotive manufacturing. The most common of these is 430 stainless steel, which is used to make components such as cutting tools, screws, bearings, and automotive parts, as well as building and decorative materials.

Order Information

- Minimum order quantity for stainless steel plates: 3 metric tons

- Payment methods: Letter of Credit (L/C) or Telegraphic Transfer (T/T)

Stainless Steel Surface Finish

NO.1 Surface: Hot-rolled, annealed, and pickled surface with a rough texture, suitable for industrial applications that require heat and corrosion resistance.

2B Surface: Cold-rolled, annealed, and pickled surface with a matte finish, processed to make the surface smooth, and easily polished for a brighter appearance.

BA Surface (Bright Annealed): Cold-rolled, annealed, and bright annealed surface with excellent glossiness and high reflectivity.

NO.4 Surface: Also known as a brushed finish, this surface is achieved by using a 150-180 grit abrasive, resulting in a continuous and unidirectional pattern of fine lines.

HL Surface (Hair Line): Hairline finish, achieved by using an appropriate grit size of abrasive to create continuous linear patterns that resemble hairlines.

NO.8 Surface (Mirror): Mirror-like finish achieved by cold-rolling and then polishing to a high shine.

Checkered Plate: Stainless steel plate with a balanced three-dimensional pattern used for anti-slip purposes.

Stainless Steel Chemical Composition & Mechanical Property (%)

| Element | Stainless Steel 201 | Stainless Steel 301 | Stainless Steel 304 | Stainless Steel 304L | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 430 |

|---|---|---|---|---|---|---|---|

| Carbon | 0.15% max | 0.15% max | 0.08% max | 0.03% max | 0.08% max | 0.03% max | 0.12% max |

| Manganese | 5.50 - 7.50% | 2.00% max | 2.00% max | 2.00% max | 2.00% max | 2.00% max | 1.00% max |

| Phosphorus | 0.06% max | 0.045% max | 0.045% max | 0.045% max | 0.045% max | 0.045% max | 0.04% max |

| Sulfur | 0.03% max | 0.030% max | 0.030% max | 0.030% max | 0.030% max | 0.030% max | 0.03% max |

| Silicon | 1.00% max | 1.00% max | 0.75% max | 0.75% max | 0.75% max | 0.75% max | 1.00% max |

| Chromium | 16.00 - 18.00% | 16.00 - 18.00% | 18.00 - 20.00% | 18.00 - 20.00% | 16.00 - 18.00% | 16.00 - 18.00% | 16.00 - 18.00% |

| Nickel | 3.50 - 5.50% | 6.00 - 8.00% | 8.00 - 10.00% | 8.00 - 12.00% | 10.00 - 14.00% | 10.00 - 14.00% | - |

| Molybdenum | - | - | - | - | 2.00 - 3.00% | 2.00 - 3.00% | - |

| Nitrogen | - | - | - | - | 0.10% max | 0.10% max | - |

| Mechanical property | Stainless Steel 201 | Stainless Steel 301 | Stainless Steel 304 | Stainless Steel 304L | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 430 |

| Yield Strength (MPa) | ≥ 310 | ≥ 260 | ≥ 205 | ≥ 170 | ≥ 205 | ≥ 170 | ≥ 205 |

| Tensile Strength (MPa) | ≥ 655 | ≥ 640 | ≥ 520 | ≥ 485 | ≥ 520 | ≥ 485 | ≥ 420 |

| Elongation (%) | ≥ 30 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 22 |

| Hardness (HV) | ≤ 200 | ≤ 200 | ≤ 200 | ≤ 200 | ≤ 200 | ≤ 200 |

- Gallery

- Related Products

316 Stainless Steel Custom-size Precision Blank

316 stainless steel custom-size precision blank, available in various sizes and specifications,...

Details301 Stainless Steel Spring Material (CSP)

HE-TIEN offers a wide range of sizes and hardness options for 301 stainless steel spring material,...

Details

316 Stainless Steel Plate | Premium Stainless Steel Coils for Industrial Excellence

Based in Taiwan since 1997, HE TIEN METAL INDUSTRY CO., LTD. specializes in high-quality stainless steel materials. Offering a comprehensive range of products including 316 Stainless Steel Plate, coils, strips, sheets, plates, and mirror sheets, we cater to diverse industrial needs. Our direct sourcing and in-house processing ensure competitive prices and unparalleled quality, serving clients globally in technology, construction, and manufacturing sectors.

HE-TIEN Metal Industry Co., Ltd. excels in processing stainless steel to produce superior quality coils, sheets, plates, strips, and mirror sheets. With over 25 years of expertise, the company emphasizes strict quality control and competitive pricing by directly sourcing and processing materials. Catering primarily to stamping and laser sheet metal manufacturers, HE-TIEN's products find wide applications across various industries, ensuring reliability and excellence.

HE-TIEN has been providing customers with stainless steel strips for industrial use since 1997, both with advanced technology and 27 years of experience, HE-TIEN ensures that each customer's needs are met.