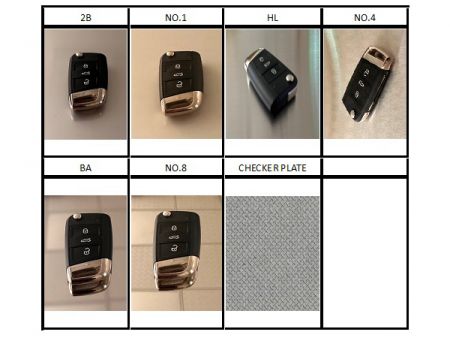

Stainless Steel Surface Treatment

Stainless Steel Surface Finish

Stainless steel can undergo various surface finishes and treatments, resulting in different appearance and gloss levels. HE-TIEN can provide suitable recommendations based on your industry application needs. Here are some common surface finishes for stainless steel:

NO.1: Also known as the mill finish, NO.1 refers to the surface of hot-rolled stainless steel. After high-temperature rolling, the surface is annealed and pickled, followed by precision rolling to achieve a bright white appearance. It has a rougher surface texture but exhibits good plasticity and ductility.

2B: The 2B surface finish is achieved by cold rolling and annealing the stainless steel, starting from NO.1 stainless steel coils, followed by acid pickling. The 2B surface has high flatness, lower glossiness, and good surface quality without significant protrusions or pits. It is relatively smooth.

BA: The BA (Bright Annealed) surface is obtained by bright annealing of 2B stainless steel. It has high surface flatness, no significant protrusions or pits, and a smooth and glossy appearance with excellent reflectivity.

NO.4: The NO.4 surface finish is also known as a brushed or satin finish. It involves grinding and polishing the 2B surface with #150 - #180 grit abrasives to effectively remove defects and roughness, resulting in a smooth and slightly textured surface. It effectively hides scratches and fingerprints, presenting a soft luster.

HL: The HL (Hairline) surface finish is achieved by grinding and polishing the 2B surface with #150 - #200 grit abrasives in a unidirectional pattern. It exhibits noticeable straight lines and is smoother compared to the NO.4 surface. The surface appears more refined.

NO.8: The NO.8 surface, also known as a mirror finish, is achieved by polishing and grinding the 2B or BA surface to create a highly smooth, bright, and reflective mirror-like effect. It is the most refined surface finish for stainless steel.

Checker Plate: Stainless steel checker plate, also known as diamond plate or tread plate, is produced by pressing a raised pattern onto the surface of the stainless steel plate. The raised pattern is typically composed of alternating diamonds or lines, providing slip resistance or anti-skid properties.

Applications of Stainless Steel Surface Finishes

NO.1: The highest surface roughness, commonly used for the production of thick plates, such as oil tanks, chemical containers, etc. Ideal for environments where durability is crucial, such as in the manufacture of heavy machinery, construction equipment, and large-scale piping systems where surface aesthetics are secondary to structural integrity.

2B: Smooth surface with slight roughness, a universal surface treatment method widely used in applications from kitchen appliances, medical devices, to pharmaceutical processing equipment due to its good corrosion resistance and a clean, minimalistic look. It's also common in roofing, cladding, and architectural trim for buildings.

BA: Smooth, flat, and bright surface with excellent reflectivity. Primarily used in high-end architecture, furniture, electronics, and other applications with high surface quality requirements. Favoured for architectural features, such as facades, lobby interiors, and elevator panels, that require a striking visual appeal. In consumer products, it's often seen on the exterior of high-quality kitchen appliances, reflective trim on premium automobiles, and decorative elements in luxury furniture.

NO.4: Clear pattern and soft texture, effectively concealing scratches and fingerprints. Mainly applied in architecture, furniture, kitchenware, electronics, automotive, and other fields, especially in applications that require high surface quality and certain scratch and fingerprint resistance. Selected for architectural details including handrails, door handles, and building facades where a directional grain is desired for aesthetic purposes. This finish is also preferred for kitchen backsplashes, countertops, and commercial food preparation areas where both appearance and ease of maintenance are important.

HL: Lower surface roughness, resembling a velvet-like effect, appearing smoother and finer. Typically used in high-end architecture, premium furniture, electronic products, and other applications that demand high surface quality. Used in high-end architectural installations, such as wall panels and decorative features that benefit from its subtle texture. The HL finish is also chosen for upscale consumer electronics and premium automotive interiors for its sophisticated appearance.

NO.8: Extremely smooth surface with high reflectivity, known as a mirror finish. Often used in high-end architecture, premium furniture, kitchenware, appliances, medical instruments, and other applications that require high surface glossiness and reflectivity. Ideal for applications requiring a mirror finish such as in luxury retail spaces, high-end hotel lobbies, and in the manufacture of reflective sculptures or art installations. It's also used for critical reflective components in optical instruments and for decorative detailing in premium automotive customization.

Checker Plate: Highly decorative surface with various patterns, applied in decoration, furniture, construction, and other areas to enhance product aesthetics and decorative effects. Commonly applied in places requiring durable, non-slip surfaces with visual appeal, such as on staircases, walkways, and decorative facades. Its pattern not only adds an element of visual interest but also enhances safety by providing improved grip, making it suitable for industrial settings, transportation facilities, and public spaces.

Stainless Steel 200 / 300 / 400 Series Characteristics

Stainless steel is typically composed of iron, carbon, chromium, nickel, cobalt, and other alloying elements. Stainless steel can be divided into three series: 200 series, 300 series, and 400 series, which differ in the type and proportion of alloying elements.

200 Series: Primarily containing nickel and manganese but no chromium, they have poorer corrosion resistance but good ductility and formability, making them easy to process and shape. Products made from 200 series stainless steel include kitchen utensils, furniture, pipes, and building structures.

300 Series: Primarily containing chromium and nickel but no molybdenum, they have excellent corrosion resistance and high-temperature performance, making them particularly suitable for use in industries such as chemical, petroleum, and food processing. The most common of these is 304 stainless steel, which has a wide range of applications including kitchen utensils, food processing equipment, medical devices, building exterior decoration, and more.

400 Series: Primarily containing chromium and molybdenum but no nickel, they have poorer corrosion resistance but good heat and wear resistance, making them particularly suitable for use in industries such as mechanical and automotive manufacturing. The most common of these is 430 stainless steel, which is used to make components such as cutting tools, screws, bearings, and automotive parts, as well as building and decorative materials.

- Gallery

- Related Products

304 Stainless Steel Spring Material (CSP)

The classification and sizes of 304 stainless steel spring materials are diverse. It includes...

Details430 Stainless Steel Mirror Sheet

HE-TIEN offers high-quality 430 stainless steel mirror sheets, known for their excellent mechanical...

Details304 Stainless Steel Checker Plate

HE-TIEN offers customizable 304 stainless steel checker plates, crafted to meet diverse industrial...

Details

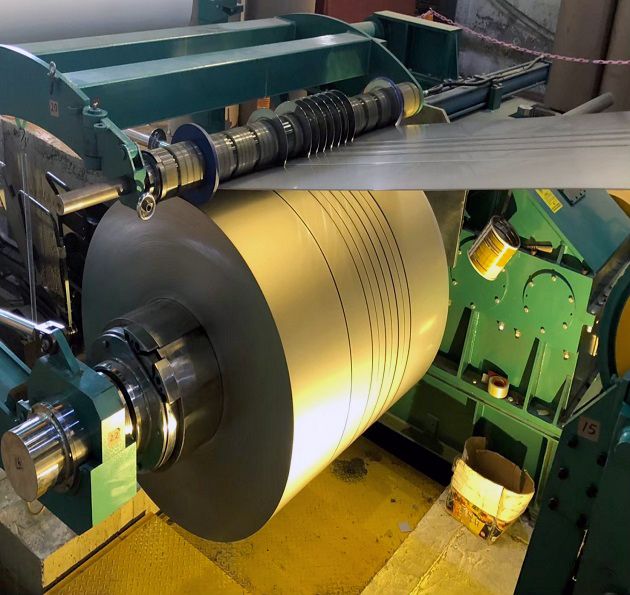

Stainless Steel Surface Treatment | Premium Stainless Steel Coils for Industrial Excellence

Based in Taiwan since 1997, HE TIEN METAL INDUSTRY CO., LTD. specializes in high-quality stainless steel materials. Offering a comprehensive range of products including Stainless Steel Surface Treatment, coils, strips, sheets, plates, and mirror sheets, we cater to diverse industrial needs. Our direct sourcing and in-house processing ensure competitive prices and unparalleled quality, serving clients globally in technology, construction, and manufacturing sectors.

HE-TIEN Metal Industry Co., Ltd. excels in processing stainless steel to produce superior quality coils, sheets, plates, strips, and mirror sheets. With over 25 years of expertise, the company emphasizes strict quality control and competitive pricing by directly sourcing and processing materials. Catering primarily to stamping and laser sheet metal manufacturers, HE-TIEN's products find wide applications across various industries, ensuring reliability and excellence.

HE-TIEN has been providing customers with stainless steel strips for industrial use since 1997, both with advanced technology and 27 years of experience, HE-TIEN ensures that each customer's needs are met.