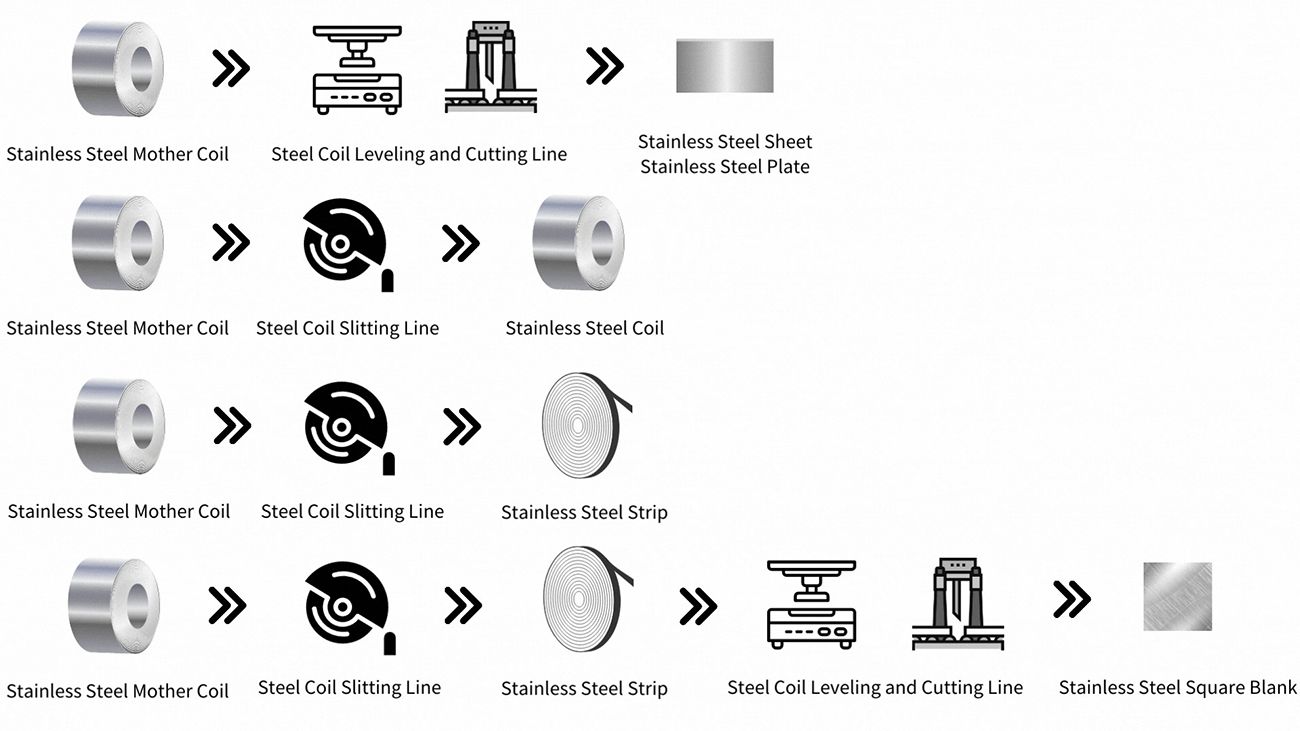

Manufacturing Process

At HETIEN METAL, we utilize an array of advanced cutting techniques to produce superior stainless steel products customized to meet our clients' specific requirements. Our expertise encompasses the processing of stainless steel coils, strips, sheets, plates, and precision blanks. With state-of-the-art equipment and meticulous attention to detail, we ensure exceptional precision and quality in every product we manufacture.

Stainless Steel Coils:

The production of stainless steel coils begins with a stainless steel mother coil. This coil undergoes an uncoiling process, followed by rough leveling to ensure an initial evenness. The edges of the coil are then trimmed to remove any imperfections. After edge trimming, the coil is slit according to specific weight requirements using a 1600mm steel coil slitting machine. This process results in stainless steel coils that meet precise specifications and are ready for further use or distribution.

Stainless Steel Strips:

Stainless steel strips are produced in two stages. Initially, a stainless steel mother coil is uncoiled and subjected to rough leveling. The coil is then slit according to the required width specifications and recoiled using a 1600mm steel coil slitting machine. This forms the primary stainless steel strips.

For further refinement, these stainless steel strips are uncoiled once more and undergo another round of rough leveling. They are then slit to even narrower width requirements and recoiled using either a 650mm or 400mm steel coil slitting machine. This secondary process ensures that the stainless steel strips meet stringent width specifications for various applications.

Stainless Steel Sheets:

The production of stainless steel sheets starts with a stainless steel mother coil. The coil is uncoiled and its edges are trimmed to remove any irregularities. Following edge trimming, the coil undergoes rough leveling and then fine leveling to achieve a smooth, even surface. The leveled coil is then cut according to specific length requirements using a combination of 1600mm steel coil leveling machines. The final product is stainless steel sheets, characterized by their precise dimensions and high-quality finish.

Stainless Steel Plates:

To produce stainless steel plates, a stainless steel mother coil is first uncoiled and its edges trimmed. The coil then goes through rough leveling to eliminate any major unevenness, followed by fine leveling for a smoother finish. Using a 2000mm plate leveling machine, the coil is cut according to the required length specifications. This process results in stainless steel plates that are robust and precisely dimensioned, suitable for various industrial applications.

Stainless Steel Precision Blanks:

The production of stainless steel precision blanks involves a multi-step process. Starting with a stainless steel mother coil, the coil is uncoiled and its edges trimmed. It then undergoes rough leveling and is slit according to the required width specifications. The slit coil is recoiled using a 1600mm steel coil slitting machine, forming intermediate stainless steel strips.

These strips are then uncoiled again and go through another rough leveling process. Fine leveling follows to ensure a high degree of surface evenness. Finally, the strips are cut to the precise length requirements using a combination of 1300mm and 800mm steel coil leveling machines. The end product is stainless steel precision blanks, known for their exact dimensions and superior surface quality, ideal for high-precision applications.

Each stage of these processes is meticulously controlled to ensure that the final stainless steel products meet the highest standards of quality and precision, catering to a wide range of industrial needs.