304L Stainless Steel Strip

AISI304L / SUS304L (1.4307)

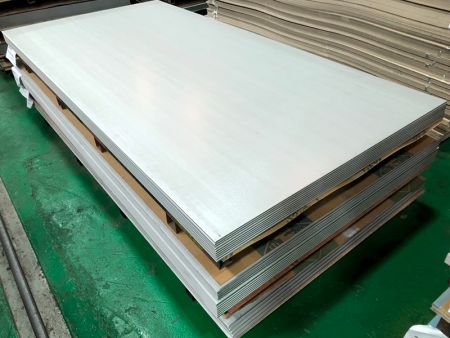

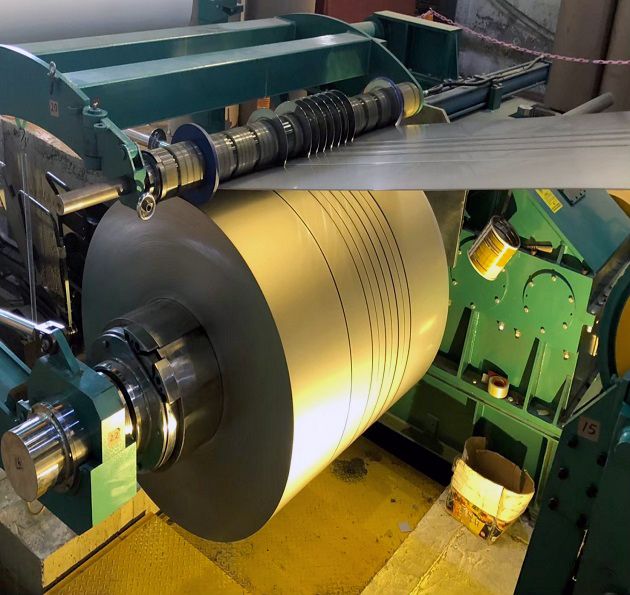

304L stainless steel strip offers excellent quality and a wide range of sizes, catering to diverse requirements across various industries. We provide AISI/SUS 304L (1.4307) grade stainless steel with thickness ranging from 0.3mm to 12.0mm. Surface finishes available include 2B, BA, NO1, NO4, HL, and NO8, while the width options range from 10mm to 1524mm. With a large inventory of steel coils and in-house processing capabilities, we can fulfill orders promptly, accommodating urgent demands. As a professional stainless steel supplier, we prioritize meeting our customers' delivery timelines and strive to provide high-quality products to support their manufacturing operations.

In today’s highly competitive market, maintaining cost efficiency is crucial. Hence, we source 304L stainless steel strips directly from steel mills, leveraging our extensive experience to effectively support our customers. Processing these strips in-house not only enhances manufacturing efficiency and precision but also positions us advantageously in terms of pricing.

We provide a range of customized services tailored to meet your specific needs. You can specify the weight, thickness, and width of the 304L stainless steel strips. Our precision edge trimming services ensure high-quality finishes. The HL and NO.4 surfaces are treated with wet sanding, resulting in a smooth, clean, and uniform appearance. We also offer double-sided sanding and additional services such as applying PE blue film, PVC black/white film, CO2 laser film, fiber laser film, and material inkjet printing, adding a professional and personalized touch to your products. Moreover we offer double-sided processing for our Bright Annealed (BA) and Mirror (NO.8) finishes, ensuring both sides of the coil achieve exceptional reflectivity and smoothness. This makes the material ideal for high-end projects where both sides need to look flawless and withstand rigorous use.

Our 304L stainless steel strips have earned widespread recognition and acclaim from customers across various countries and industries. We serve a broad spectrum of sectors including food service, transportation, medical devices, renewable energy, semiconductors, electronics, environmental engineering, and biotechnology. The superior characteristics of our 304L stainless steel strips, such as excellent corrosion resistance, durability, and aesthetic appeal, make them suitable for a wide array of applications.

Beyond our high-quality products, we are committed to providing exceptional customer service. Our knowledgeable team is dedicated to understanding your unique requirements and delivering tailored solutions that meet your specific needs. We maintain a robust inventory to ensure timely delivery and consistent supply, minimizing downtime and enhancing productivity for your operations.

Sustainability is a core aspect of our operations. We pride ourselves on being an extremely eco-friendly company that does not discharge wastewater or emissions. By implementing advanced manufacturing processes and strict environmental controls, we ensure that our production activities do not harm the environment.

Our 304L stainless steel strips are known for their reliability and high performance. Whether you need standard sizes or custom processing, we cater to the diverse needs of various industrial and commercial applications. Our products are widely used in construction, automotive, aerospace, electronics, and consumer goods industries, demonstrating their versatility and adaptability.

If you are seeking a high-quality supplier of 304L stainless steel strips, we are confident in our ability to provide satisfactory services and products. Contact us today to discover how we can fulfill your stainless steel needs.

Product Specification

- ASTM A240/A240M/A480/A480M

- JIS G4305/G4304

- EN 10028-1/10088-2

Stainless Steel 304L Features and Applications

304L stainless steel strip is a commonly used stainless steel alloy, consisting of 18% chromium, 8% nickel, and small amounts of carbon, manganese, phosphorus, sulfur, and other elements. Its chemical composition gives it excellent corrosion resistance, high-temperature resistance, good formability, weldability, and deep-drawing properties, making it widely used in the industrial sector.

304L stainless steel strip is the low-carbon version of stainless steel strip 304. Compared to 304, 304L has a lower carbon content, resulting in improved corrosion resistance and weldability. Specifically, 304L offers the following advantages:

Improved Corrosion Resistance: Due to its low carbon content, 304L exhibits better corrosion resistance, especially during welding. It is commonly used in applications that require high corrosion resistance, such as chemical, pharmaceutical, and food processing industries.

Enhanced Weldability: The low carbon content of 304L makes it easier to weld and reduces the risk of intergranular corrosion after welding. It is often used in applications that require welding, such as pipelines, storage tanks, and other containers.

Overall, 304L stainless steel finds wide application in industries that require high corrosion resistance and weldability, including pharmaceuticals, food processing, chemical, oil and gas extraction, and marine engineering.

Stainless Steel 200 / 300 / 400 Series Characteristics

Stainless steel strip is typically composed of iron, carbon, chromium, nickel, cobalt, and other alloying elements. Stainless steel can be divided into three series: 200 series, 300 series, and 400 series, which differ in the type and proportion of alloying elements.

200 Series: Primarily containing nickel and manganese but no chromium, they have poorer corrosion resistance but good ductility and formability, making them easy to process and shape. Products made from 200 series stainless steel include kitchen utensils, furniture, pipes, and building structures.

300 Series: Primarily containing chromium and nickel but no molybdenum, they have excellent corrosion resistance and high-temperature performance, making them particularly suitable for use in industries such as chemical, petroleum, and food processing. The most common of these is 304 stainless steel, which has a wide range of applications including kitchen utensils, food processing equipment, medical devices, building exterior decoration, and more.

400 Series: Primarily containing chromium and molybdenum but no nickel, they have poorer corrosion resistance but good heat and wear resistance, making them particularly suitable for use in industries such as mechanical and automotive manufacturing. The most common of these is 430 stainless steel, which is used to make components such as cutting tools, screws, bearings, and automotive parts, as well as building and decorative materials.

Order Information

- Minimum Order Quantity for Stainless Steel Strip: Depends on the width of the stainless steel strip

- Payment Method: Letter of Credit (L/C) or Telegraphic Transfer (T/T)

Stainless Steel Surface Finish

NO.1 Surface: Hot-rolled, annealed, and pickled surface with a rough texture, suitable for industrial applications that require heat and corrosion resistance.

2B Surface: Cold-rolled, annealed, and pickled surface with a matte finish, processed to make the surface smooth, and easily polished for a brighter appearance.

BA Surface (Bright Annealed): Cold-rolled, annealed, and bright annealed surface with excellent glossiness and high reflectivity.

NO.4 Surface: Also known as a brushed finish, this surface is achieved by using a 150-180 grit abrasive, resulting in a continuous and unidirectional pattern of fine lines.

HL Surface (Hair Line): Hairline finish, achieved by using an appropriate grit size of abrasive to create continuous linear patterns that resemble hairlines.

NO.8 Surface (Mirror): Mirror-like finish achieved by cold-rolling and then polishing to a high shine.

Checkered Plate: Stainless steel plate with a balanced three-dimensional pattern used for anti-slip purposes.

Stainless Steel Chemical Composition & Mechanical Property (%)

| Element | Stainless Steel 201 | Stainless Steel 301 | Stainless Steel 304 | Stainless Steel 304L | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 430 |

|---|---|---|---|---|---|---|---|

| Carbon | 0.15% max | 0.15% max | 0.08% max | 0.03% max | 0.08% max | 0.03% max | 0.12% max |

| Manganese | 5.50 - 7.50% | 2.00% max | 2.00% max | 2.00% max | 2.00% max | 2.00% max | 1.00% max |

| Phosphorus | 0.06% max | 0.045% max | 0.045% max | 0.045% max | 0.045% max | 0.045% max | 0.04% max |

| Sulfur | 0.03% max | 0.030% max | 0.030% max | 0.030% max | 0.030% max | 0.030% max | 0.03% max |

| Silicon | 1.00% max | 1.00% max | 0.75% max | 0.75% max | 0.75% max | 0.75% max | 1.00% max |

| Chromium | 16.00 - 18.00% | 16.00 - 18.00% | 18.00 - 20.00% | 18.00 - 20.00% | 16.00 - 18.00% | 16.00 - 18.00% | 16.00 - 18.00% |

| Nickel | 3.50 - 5.50% | 6.00 - 8.00% | 8.00 - 10.00% | 8.00 - 12.00% | 10.00 - 14.00% | 10.00 - 14.00% | - |

| Molybdenum | - | - | - | - | 2.00 - 3.00% | 2.00 - 3.00% | - |

| Nitrogen | - | - | - | - | 0.10% max | 0.10% max | - |

| Mechanical property | Stainless Steel 201 | Stainless Steel 301 | Stainless Steel 304 | Stainless Steel 304L | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 430 |

| Yield Strength (MPa) | ≥ 310 | ≥ 260 | ≥ 205 | ≥ 170 | ≥ 205 | ≥ 170 | ≥ 205 |

| Tensile Strength (MPa) | ≥ 655 | ≥ 640 | ≥ 520 | ≥ 485 | ≥ 520 | ≥ 485 | ≥ 420 |

| Elongation (%) | ≥ 30 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 22 |

| Hardness (HV) | ≤ 200 | ≤ 200 | ≤ 200 | ≤ 200 | ≤ 200 | ≤ 200 |

- Gallery

- Related Products

304L Stainless Steel Sheet

We offer a wide range of high-quality 304L stainless steel sheets to meet the diverse needs...

Details304L Stainless Steel Plate

304L stainless steel plates offer excellent quality and a wide range of size that can meet...

Details

304L Stainless Steel Strip | Premium Stainless Steel Coils for Industrial Excellence

Based in Taiwan since 1997, HE TIEN METAL INDUSTRY CO., LTD. specializes in high-quality stainless steel materials. Offering a comprehensive range of products including 304L Stainless Steel Strip, coils, strips, sheets, plates, and mirror sheets, we cater to diverse industrial needs. Our direct sourcing and in-house processing ensure competitive prices and unparalleled quality, serving clients globally in technology, construction, and manufacturing sectors.

HE-TIEN Metal Industry Co., Ltd. excels in processing stainless steel to produce superior quality coils, sheets, plates, strips, and mirror sheets. With over 25 years of expertise, the company emphasizes strict quality control and competitive pricing by directly sourcing and processing materials. Catering primarily to stamping and laser sheet metal manufacturers, HE-TIEN's products find wide applications across various industries, ensuring reliability and excellence.

HE-TIEN has been providing customers with stainless steel strips for industrial use since 1997, both with advanced technology and 27 years of experience, HE-TIEN ensures that each customer's needs are met.